The Council held its annual board meeting in Valdez, Alaska, on May 2-3, 2024. Among other business, the Board convened to elect officers who will serve from May 2024 to May 2025.

The Council held its annual board meeting in Valdez, Alaska, on May 2-3, 2024. Among other business, the Board convened to elect officers who will serve from May 2024 to May 2025.

The elected executive committee is comprised of:

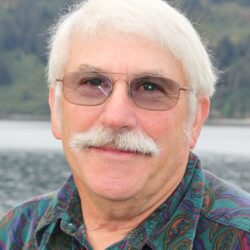

- President: Robert Archibald, representing the City of Homer

- Vice President: Amanda Bauer, representing the City of Valdez

- Treasurer: Mako Haggerty, representing the Kenai Peninsula Borough

- Secretary: Bob Shavelson, representing the Oil Spill Region Environmental Coalition

- Three Members-at-Large:

- Ben Cutrell, representing Chugach Alaska Corporation

- David Janka, representing City of Cordova

- Angela Totemoff, representing the Community of Tatitlek

“Of all the advances made in the safe transportation of oil since the 1989 Exxon Valdez oil spill, perhaps the most innovative and significant was the establishment of permanent, industry-funded citizen oversight for both Cook Inlet and Prince William Sound,” Robert Archibald said. “Everyone involved should be proud of what has been accomplished since the spill, but we also should never become so satisfied with the current services or processes that we become complacent. Constant vigilance is needed to prevent a return to the pre-1989 complacency that allowed this disaster to happen. I am honored to lead our board for another year as we work toward our shared goal of protecting our communities, economies and environment.”

The Council is grateful to have the support of its many volunteers from all over the Exxon Valdez oil spill region. The new executive committee is an excellent representation of the Council.

Meet the Executive Committee

Media release: PWSRCAC May 2024 Board officers press release